|

|

Most

Seabee owners and pilots agree that one of the few weak points of an original RC-3 Seabee

is the lack of engine power. The original

engine installation was a 215 hp Franklin Model 6A8-215-B8F/-B9F six cylinder

engine. The Seabee is a large airplane and with the Franklin

engine the power-loading is quite high.

The huge cabin of the Seabee invites pilots to

overload the airplane, and on a hot day a heavy loaded Franklin-powered

Seabee will be a challenge to get in the air...

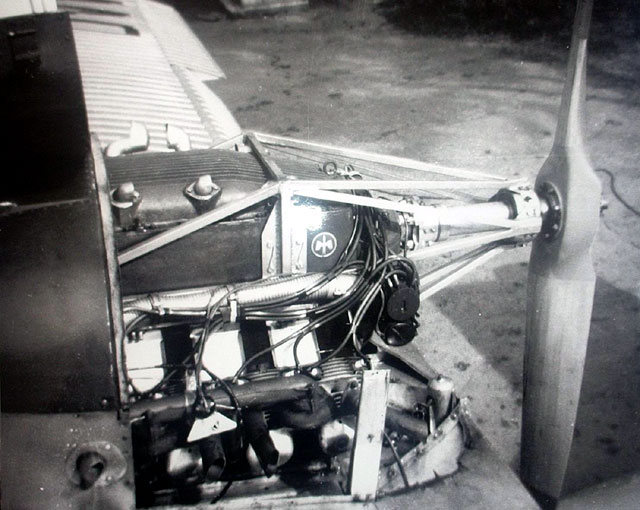

Simuflight Lycoming GO-480 Engine Conversion

Photo: © Mark Becker

Engine conversions therefore have been among the most

popular of the many modifications developed for the Seabee, after

production ceased in 1947. Many experimental one-of-a-kind

engine installations have been developed, including gas turbine

engines. Some of the engine conversions have been STC'ed and are offered commercially by a few companies. The Lycoming GO-480

geared engine conversions have become the most popular. However, the

Lycoming GO-480-series engines are no longer in production (since 1979). Direct drive

Lycoming IO/TIO-540 engine conversions have also been installed on a

number of Seabees. The O-540-series engines are still in

production at Lycoming.

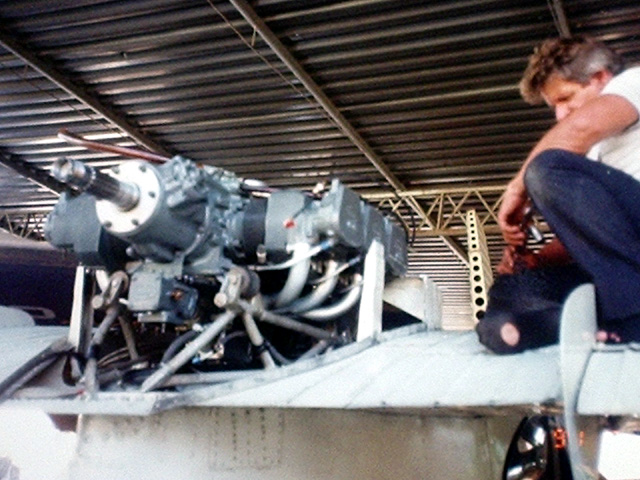

TAC Lycoming IO/TIO-540 Engine Conversion

Photo: © Randy Komko

The newest Seabee engine

conversions to emerge are the Robinson V8 engine conversions,

developed by Mr. Brian Robinson in Canada. The Robinson conversions

utilize a 320 hp LS-1 or a 350 hp LS-6 Corvette G.M. V8 engine.

Twenty-three Seabees have been converted to twin

engine configuration, through the STOL UC-1 Twin Bee conversion.

Actually, the Twin Bee conversion is so extensive that it requires a new

Aircraft Type Certificate.

|

|

Franklin Standard Engines

|

|

W.S.K. -

PZL-Rzeszow

Ul. Hetmanska 12

PL-35 078 Rzeszow

Poland

|

The original engine installation on

manufacture at Republic in 1946/47, was

the 215 hp Franklin 6A8-215-B8F/B9F six cylinder. The RC-3

prototype / pre-production aircraft originally had a Model -B7F

installed. The Type

Certificate for the Franklin engines is currently held by a Polish

company.

Specifications

- Franklin 6A8-215-B8F/-B9F |

| Manufacturer |

Aircooled Motors, Inc. |

| Address |

Syracuse 8, New York, USA |

| Models |

6A8-215-B8F

and 6A8-215-B9F |

| Approved Type Certificate No. |

E-242 |

| Weight - dry |

432 lbs (incl.

cooling fan and oil cooler) |

| Number of Cylinders |

6 |

| Rated Power |

215 hp |

| Rated Speed |

2500 rpm |

| Idle Speed |

500 - 600 rpm |

| Reverse Propeller Speed |

(Max)

1750 rpm |

| Crankshaft Rotation |

Clockwise |

| Propeller Shaft Rotation |

Clockwise |

| Propeller to Crankshaft Ratio |

1:1 |

| Propeller Shaft Spline Size |

SAE 20 |

| Cylinder Head Temperature |

Max. 525 ° F |

| Fuel Grade |

80 Octane Nonleaded Aviation |

| Fuel Consumption (Cruise) |

13.5

US gal/hr |

| Fuel Pressure |

2 to 9 psi |

| Compression Ratio |

7:1 |

| Piston Displacement |

500 cu in |

| Bore |

5 cu in |

| Stroke |

4.25

cu in |

| Fuel Pump |

Dual AC Diaphragm Type |

| Carburetor |

Marvel-Schebler MA4-5 # 10-3007 |

| Ignition (-B8F) |

Dual Eisemann Magneto Model LA-6 |

| Ignition (-B9F) |

1 Scintilla Magneto + 1 Auto-Lite

Distr. |

| Magneto Breaker Point Gap |

(Eisemann)

.019" to .021" |

| Distributor Point Gap |

(Auto-Lite)

.020" |

| Maximum Drop on Magneto or Distributor |

100 RPM |

| Ignition Timing |

32

º Adv. Left and Right |

| Firing Order |

1-4-5-2-3-6 |

| Spark Plugs |

Auto Lite AH4 |

| Spark Plug Gap |

.014" to .018" |

| Valve Clearance |

(lifter

bled down, cold) .040" |

| Starter |

12 Volt, Delco |

| Generator (Max 35 Ampere) |

E.AL. GGS-4801A-EO-8686 |

| Oil Capacity |

13 qts |

| Oil Temp (Max) |

260 ° F |

| Oil Pressure (Max) |

50 psi |

| Oil Pressure (Idle Min) |

20 psi |

| Oil Capacity (thru MSN 24065) |

11 qts |

| Oil Capacity (MSN 24066 and on) |

12 qts |

| Oil Specifications (Above 40 F) |

SAE 40 |

| Oil Specifications (Below 20 F) |

SAE 20 |

| Max Time Between Oil Changes |

25 hrs

|

|

|

Continental IO-470-P Engine Conversions

|

N6432K (#682)

George Pappas Continental IO-470-P engine conversion

Photo: © courtesy of Nancy and Randy Rhodes

In

the late 1960s, expert mechanic and world class metal craftsman George

Pappas installed a 250 hp Continental IO-470-P engine in his Seabee

N6432K (MSN 682) in Anchorage, Alaska, where Pappas owns a company

called Aircraft Rebuilders. Pappas also designed his special

cowlings for the Continental conversion. His conversion also have a

reversible propeller.

The original "Pappas" cowling was very

sleek and beautiful, as shown in the above photo. However, it

seems that one of the later owners modified the cowling by widening

the inlet, probably to improve cooling.

The Continental IO-470-P engine was originally

installed on the Italian NARDI / SIAI-Marcehtti FN.333 Riviera

amphibian. The supply of IO-470-P engines is less than plentyfull

and therefore this engine is quite expensive. Actually the

IO-470-P conversion has never been STCed. However, at least four

more Seabees are reported to have been modified with IO-470-P engines

under 'experimental' category; N124AC (MSN 60), N6056K

(MSN

231), N6668K

(MSN 945) and N6747K (MSN

1035).

Specifications

- Continental IO-470-P |

| Manufacturer |

Teledyne

Continental Motors |

| Address |

Mobile,

Alabama, USA |

| Models |

IO-470-P |

| Approved Type Certificate No. |

3E1 |

| Weight - dry |

472

lbs |

| Number of Cylinders |

6 |

| Rated Power (T/O) |

250 hp |

| Rated Speed (T/O) |

2600 rpm |

| Idle Speed |

? rpm |

| Reverse Propeller Speed |

? rpm |

| Crankshaft Rotation |

Clockwise |

| Propeller Shaft Rotation |

Clockwise |

| Propeller to Crankshaft Ratio |

1:1 |

| Propeller Shaft Spline Size |

SAE 20,

extended shaft with provision for hydraulic propeller control and

revering. |

| Cylinder Head Temperature |

Max.

460 ° F |

| Cylinder Barrel

Temperature |

Max.

290 ° F |

| Oil Inlet

Temperature |

Max.

225 ° F |

| Fuel Grade |

91/96 Aviation |

| Fuel Consumption (Cruise) |

? US gal/hr |

| Fuel Pressure |

-2 to

+10 psig |

| Compression Ratio |

8.0:1 |

| Piston Displacement |

471 cu in |

| Bore |

5.00

cu in |

| Stroke |

4.00

cu in |

| Fuel Pump |

? |

| Fuel Injection |

TCM

Injector (Eq. 5648) |

| Ignition (dual

magnetos) |

? |

| Magneto Breaker Point Gap |

?" to

?" |

| Distributor Point Gap |

?" |

| Maximum Drop on Magneto or Distributor |

100 RPM |

| Ignition Timing |

26

º BTC |

| Firing Order |

1-4-5-2-3-6 |

| Spark Plugs |

Auto

Lite SH26. SH260 |

| Spark Plug Gap |

?

" |

| Valve Clearance |

(lifter

bled down, cold) ?

" |

| Starter |

? Volt |

| Generator |

? Volt,

? Ampere |

| Oil Sump Capacity |

12 qts |

| Oil Temp (Max) |

235 ° F |

| Oil Pressure (Max) |

100 psi |

| Oil Pressure

(Normal) |

30 -

60 psi |

| Oil Pressure (Idle Min) |

10 psi |

| Oil Capacity |

12 qts |

|

|

'Daubenspeck' Engine Conversions

|

|

STC Bee, Inc.

10900 Rainier Avenue S.

Seattle, WA 98178

USA

|

In

the late 1960s engineer and Seabee owner Jack Daubenspeck, Seattle,

Washington, started to develop Seabee modifications. Daubenspeck

soon formed the company Aerocraft Inc. and initially designed, produced

and marketed some very popular fiberglass 'droop' wing tips for the

Seabee. He also started the design and development of new Seabee

engine conversions utilizing the Lycoming GO-435/GO-480 geared

engines.

At some stage of the development, Aerocraft Inc.

started accepting predelivery deposits from eager Seabee owners who

wanted to give their Seabees 'new' power. Unfortunately, engineering

problems continued and the company was forced to close down when some of

the Seabee owners lost their patience and wanted their deposits

back. The prototype 'Daubenspeck' Seabee was sold to cover the

claims, and was never flown with the Lycoming engine under Daubenspeck's

ownership.

Seabee

owner John Greeff did not loose confidence in Daubenspeck and contracted

him to finish the Lycoming GO-435/GO-480 engine conversion for his Seabee,

N6456K (MSN 707). With Mr. Greeff funding the company, Greeff and

Daubenspeck started the company 'STC Bee, Inc.' to produce and market

Daubenspeck's Seabee modifications.

For the ' Daubenspeck' engine conversion a new

"scoop type" glas fibre cowling was designed. Most

Daubenspeck conversions will be recognized by this beautiful cowling.

However, it is generally agreed that the 'Daubenspeck' cowling is

heavier (55 lbs vs 22 lbs) and less maintenance-friendly than the

'Simuflight' cowling.

The Daubenspeck Lycoming GO-435/GO-480 engine

conversions were FAA approved on 13 April 1976. Originally the

1976 FAA STC # SA-282-NW was issued for the Lycoming GO-435-series with 260 hp, the

GO-480B-series producing 270 hp on 80/87 octane fuel, the

GO-480F-series producing 275 hp on 80/87 octane fuel; and the

GO-480C/G-series

which puts out 295 hp on 100/130 octane. Approval is for engines

with rear mounted accessories and either splined or flanged output

shafts. Propellers for all approved engines are 84" diameter,

three blade, constant speed and reversible. Fabricated sheet metal

parts for the STC kits were manufactured by Robertson (STOL) Aircraft.

STC Bee,

Inc. went out of business in 1985, and Mr. Daubenspeck died year 2000.

In May 2004 it is reported that Jack's son, Mr. John A. Daubenspeck is

working on re-introducing the 'Daubenspeck' conversions and

modifications.

STC

Bee held the following STC for engine conversion:

STC No: SA282NW - Installation

of Lycoming GO-480-B1D (270 hp @ 3400 RPM), GO-480-G1D6/G2D6 (295 hp @ 3400 RPM)

engine and Hartzell HC83X20-2CL propeller.

[Issued 1976-04-13].

Specifications

- Lycoming GO-480-G1D6 |

| Manufacturer |

AVCO

Lycoming |

| Address |

Williamsport,

Pennsylvania, USA |

| Models |

GO-480-G1D6 |

| Approved Type Certificate No. |

E-275 |

| Weight - dry |

444

lbs |

| Number of Cylinders |

6 |

| Rated Power (T/O) |

295 hp

(GO-480-G1D6) |

| Rated

Engine Speed (T/O) |

3400 rpm |

| Propeller

Speed (T/O) |

2170

rpm |

| Idle Speed |

500 - 600 rpm |

| Reverse Propeller Speed |

? rpm |

| Crankshaft Rotation |

Clockwise |

| Propeller Shaft Rotation |

Clockwise |

| Propeller to Crankshaft Ratio |

77

: 120 |

| Propeller Shaft Spline Size |

SAE 20 |

| Cylinder Head Temperature |

Max.

475 ° F |

| Cylinder Barrel

Temperature |

Max.

350 ° F |

| Oil Inlet

Temperature |

Max.

235 ° F |

| Fuel Grade |

100/130

LL Aviation |

| Fuel Consumption (Cruise) |

? US gal/hr |

| Fuel Pressure |

2 to 9 psi |

| Compression Ratio |

8.70:1 |

| Piston Displacement |

479.7 cu in |

| Bore |

5.125

cu in |

| Stroke |

3.875

cu in |

| Fuel Pump |

Lear-Romex |

| Carburetor |

Bendix

PS-5BD |

| Ignition (dual) |

Bendix

S6LN-21 (Left)

Bendix S6LN-20 (Right) |

| Magneto Breaker Point Gap |

.019" to .021" |

| Distributor Point Gap |

?" |

| Maximum Drop on Magneto or Distributor |

100 RPM |

| Ignition Timing |

28 deg Adv. Left and Right |

| Firing Order |

1-4-5-2-3-6 |

| Spark Plugs |

Auto Lite AH4A |

| Spark Plug Gap |

.016" |

| Valve Clearance |

(lifter

bled down, cold) .040" |

| Starter |

24

Volt |

| Generator |

24

Volt, 50 Ampere |

| Oil Capacity |

12 qts |

| Oil Temp (Max) |

235 ° F |

| Oil Pressure -

Normal (Min - Max) |

65 -

85 psi |

| Oil Pressure (Idle Min) |

25 psi |

| Oil Sump Capacity |

12 qts |

|

|

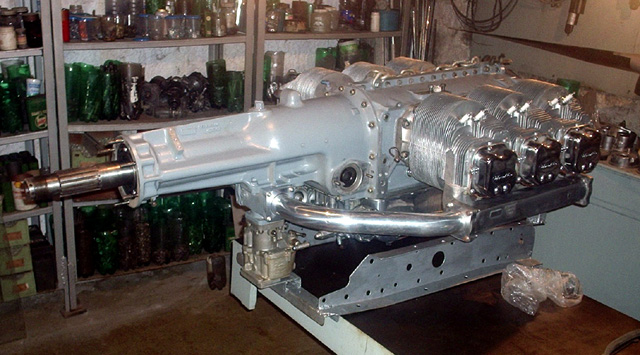

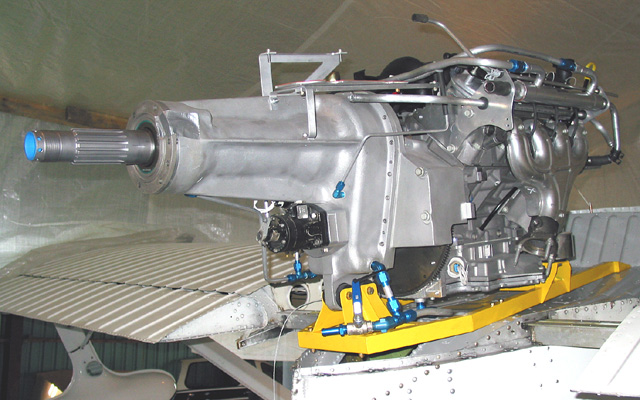

Robinson V8 Engine Conversions

|

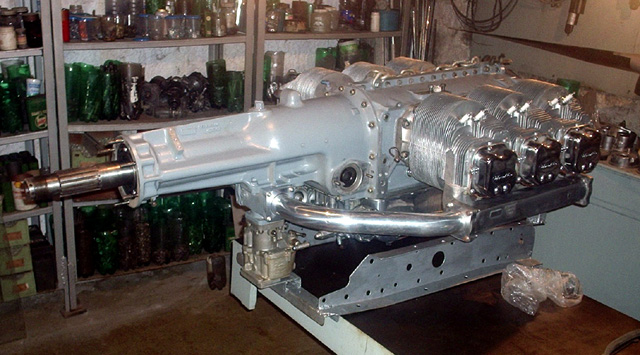

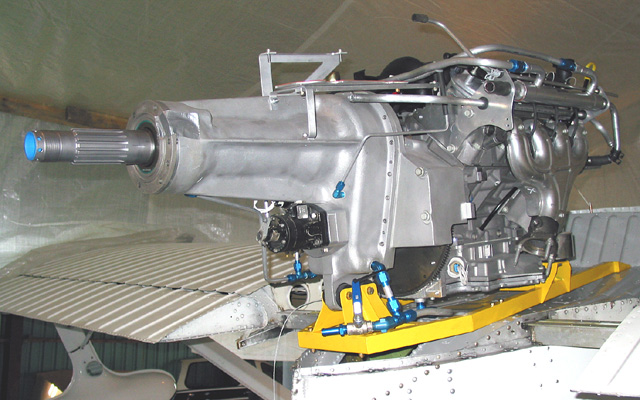

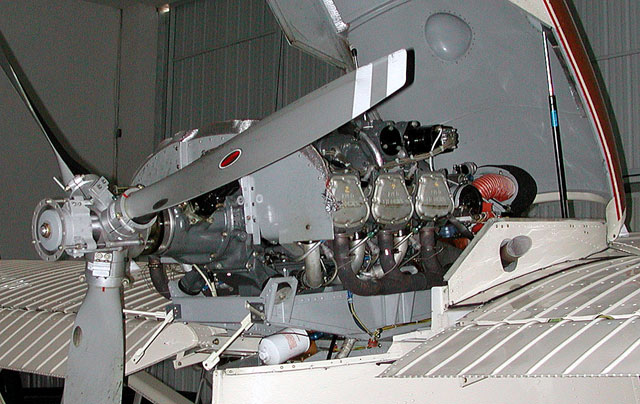

The Robinson engine conversion is the newest on the

market, and has stirred a huge interest among Seabee owners.

Developed by Canadian Brian Robinson, the conversion utilize a Corvette

V8 automobile engine mated to a cast aluminum reduction drive designed

specifically for the Seabee.. To date the Robinson's have developed &

flown the 320 hp LS1 version & the 350 hp LS6 version. Late

2005 the new 350 hp LS2 and 400 hp LS7 versions were installed in

the first Seabees.

The conversions have been successfully

flown using both standard Seabee 2 and 3 blade propellers and modern 4

blade MT propellers. Robinson has also developed a system which uses the Hartzell constant

speed reversible propeller from a GO-480 powered Seabee.

The engine can use both premium unleaded automotive

fuel and 100 LL aviation fuel.

Robinson V8 Engine Conversion

Photo: © Brian Robinson

August

2005:

Brian Robinson reported that interest in the V8 powered Seabee

continued to grow. Seven converted Seabees were flying, and four more

were under conversion. The first U.S. licensed V8 powered Seabee is the

"Tahoe Special". Rebuilt from the ground up by Steve

Lantz

& Paul Shepard, the Tahoe Special is powered by an LS6 coupled to a

four-blade MT reversible propeller. The aircraft won the Grand Champion

Seaplane award at EAA Airventure 2005 in Oshkosh! Based at Carson,

City Nevada, they often fly from land or water with density altitudes in

the 9000’ range.

Steve

& Paul consider the air conditioning essential for operating in

their climate.

Total

fleet time is approximately 1800 hrs.

The highest time V8 Seabee is Brian's own airplane CF-ILM. It has accumulated 1176 hours.

The longest trip has been from

Balsam

Lake to

Key West

Florida

and return. They use

whatever fuel is available, automotive or aviation. The aircraft

continues to perform flawlessly. The V8 installation has been operated

from sea to level to 10,000 ft, and in temperatures ranging from -20°F

to 113°F.

November

2014:

|

We flew the original installation 2,098

hours in the period from 4 July 2000 to 23 Dec 2011. During

that time the aircraft performed far above my expectations.

The engine and PSRU was performing well when it was removed.

We removed it because my system was becoming dated. My

aircraft was the first V 8 conversion done. It was running an

LS 1 with a manual throttle standard Seabee Hartzell 3 blade

propeller and our 1.68:1 reduction ratio. Most of my customers

use the 1.98:1 ratio with an electric throttle.

The Bee had a conventional (dated) panel

and was in need of some upgrading. We refurbished ILM with

many improvements including a new LS 3 sporting a modified

Edelbrock supercharger, a new design single leaver control

system that combines throttle, pitch, reverse &

supercharger control functions in one unit, and a new design

data link that allows the engine data to be sent directly from

the engine control unit to the new MGL IEFIS based panel. The

data link avoids the hassle of wiring in engine sensors and

has the benefit of letting the pilot monitor the actual GM

engine sensors that control the engine.

We were back in the air 14 Jan 2014 and

now have 99 hours on the new installation. I am really happy

with the performance of the new engine and associated

systems.

I am sure ILM is one of most highly modified Seabee ever

flown. The list of modifications are as follows: (Ed: too

long to list here, see C-FILM )

I have not documented any performance

numbers. For them to mean anything I would have to calibrate

all the instruments & standardize the data. Sufficient to

say I have flown ILM in side by side comparisons with many

Seabees, and none of them have come close to matching the

performance. The LS 3 is a noticeable improvement over the LS

1. I have only had the new engine to 10,000’ but I was able

to still pull 30” HG. Someday I will borrow an oxygen system

and explore the higher elevations.

These days my focus has shifted from the Seabee to trying to

raise capital to build the prototype of our new Horizon X2 -

the first amphibian you can land on the water with the wheels

down without hurting yourself!

Visit our website www.V8Seabee.com

and check out the Conversion Kits/Current status and Horizon

X2 tabs for more pictures and information.

Regards

Brian

E-mail dated November 21, 2014

|

|

|

|

The Robinson

Horizon X2

The Next Generation Seabee! |

USA Licensing Options

In

the U.S. the only viable licensing option Robinson has been able to

identify is compliance with the amateur built rules. In theory the

aircraft could be licensed by using a one time STC or via the 337

processes. We have been unable to find an inspector willing to do this.

The amateur built process is as follows

You

currently cannot take a certified aircraft & license it as an

amateur built aircraft. You can however build an amateur built aircraft

using mostly certified aircraft components. This is only practical if

the airframe is going to be refurbished. The process begins by removing

the Manufacturers nameplate & ensuring the aircraft has been removed

from the registry. You must then simply comply with the "51%"

rule checklist. The only confusing part is that the 51% checklist has

nothing to do with 51% of the work being done. It is simply a scorecard.

You the owner must complete 51% of the items on the FAA approved

checklist. There have been several Cessna 185 & 206

"replicas" built & licensed as amateur built aircraft.

These aircraft are eligible for export to Canada & are permitted to

cross the border. You may also import a Canadian amateur built aircraft

into the U.S. It is important to note you cannot call the aircraft a

Seabee. It must be called something else, e.g. A Robinson V-8 powered

Bee. The name Seabee refers to a certified aircraft. If you call the FAA

& tell them you are going to build an amateur built Seabee you will

be turned down. If you call the FAA & tell them you are going to

build a Robinson V-8 powered Bee (or any other name of you're choice) -

an all aluminum, V-8 powered amphibian using modified Seabee components

- they will inform you that you must comply with the 51% rule and

instruct you to complete a 51% evaluation sheet. If your project meets

the 51% criteria, it will be eligible for registration as an amateur

built aircraft. The checklist is found on the FAA web site.

Robinson V8 Engine Conversions

C-FDOQ (MSN 934), CF-ILM (s/n

881) and C-GHQU (s/n

639)

Photo: © Brian Robinson

Below is a description of the protoype LS1

installation as installed on Robinson's Seabee CF-ILM.

Engine

- The LS1, Corvette version, was a stock unit as purchased new from GM.

It is rated at 345 HP @ 5600 RPM and produces 350 ft lbs torque @ 4400

RPM. The engine has been mated to a custom built 1.7:1 reduction unit.

The engine was de-rated to approximately 320 HP by limiting the engine

to 4500 RPM. This permitted the prop to turn @ 2600 RPM. (Maximum rating

for the Hartzell Propeller installed on CF-ILM). Robinson believed

that de-rating the engine should help him reach his number one objective

- reliability. A large engine working at less than maximum power

should last significantly longer than a small engine that is working

it's heart out...

The engine was equipped with stock Corvette

exhaust manifolds, machined to remove excess weight and mated to

dual stainless steel mufflers. The mufflers and pipes were

insulated reduce the heat buildup under the cowling.

The electric throttle body actuator was removed

and replaced with the cable controlled mechanical throttle body

actuator (KISS).

The engine was equipped with the stock GM air

conditioning compressor.

The stock alternator was lowered to the same

position used on the Camaro version of the LS-1 to provide

clearance for the stock Seabee cowlings.

Reduction

Unit - The reduction drive was custom designed to fit the Seabee

installation using AutoCAD. It is based on standard Morse Hi VO chain

and sprockets, and was sized and installed as per their technical

publication. The chain is lubricated with engine oil via a spray bar.

Morse does not condone the use of their product in aircraft. The

aluminum housing was cast, aged and tempered in a local foundry. All

machining was done locally on a milling machine equipped with a digital

readout. The design was loosely patterned off of the existing Franklin

engine extension, with changes as required to maintain the existing

thrust line and propeller position.

All thrust loads (forward and reverse) are carried by

the rear reduction unit bearing. This is a copy of the Franklin setup

and the thrust bearing used is the same as the original. The propeller

pitch control system is identical to the Franklin set up. It has proven

to be trouble free over the years. Oil return is by gravity to the

engine sump, and all oil is filtered through a custom remote oil

filtering system. The drive mates to the engine via a splined adapter

bolted directly to the flywheel. The heavy manual version of the

flywheel was used as a safeguard against any potential vibration

concerns.

Cooling

System - The liquid cooling is provided by a stock Corvette

radiator, complete with stock electric cooling fans controlled by the

computer. A manual over ride switch for the fans was added so that

the pilot can turn the fans on anytime he pleases. The stock air

conditioning condenser is mounted in front of the radiator as it is in

the Corvette.

Fuel - Fuel

is supplied via manually controlled dual electric fuel pumps, complete

with a water separator and dual automotive filters. Operating pressure

range is 58 - 62 PSI. The LS1 will run on either premium

automotive fuel or 100 Low Lead aviation fuel.

Engine

Control System - The system chosen was a standard GM system.

The unit is programmed with the export code for leaded fuel and uses no

oxygen sensors. This was to enable owner to run 100 octane Low Lead fuel

as well as premium unleaded fuel. It also meets the KISS criteria. The

emission and VAT codes are suppressed. The computer is stock GM. After

much research and correspondence, the wiring harness was purchased from

an after market supplier. This portion of the project was as time

consuming as designing the reduction drive. Robinson learned that it is

imperative for a project like this to purchase the factory (not after

market) manuals for the engine and read them thoroughly. You have to

decide what is acceptable practice, how you want your engine management

system to work, and have the harness manufactured accordingly.

The option of installing a second (backup) computer

was discussed with many individuals. The resulting opinion was that the

computer used is extremely reliable. The risk of a total computer

failure is probably in the same league as a crankshaft or timing chain

failure. The installation of a second computer would make the wiring

harness considerably more complicated and increase the risk of a wiring

harness/switching circuit failure. In the Robinson installation,

Computer Power is supplied from one of two full size batteries. The

batteries can be manually isolated in case of an alternator failure. The

computer power source is selected manually.

Wiring

Harness - The harness must be integrated into the airframe.

Robinson believes that the odds of a wiring harness failure are greater

than the risk of a mechanical failure (and you probably will get less

warning). The harness utilizes crimped and/or soldered terminals. A good

quality crimper was purchased and mil spec terminals and wires were used

throughout. Routing, visibility, protection and security of the harness

were installation priorities.

|

| Manufacturer |

GM |

GM |

GM |

GM |

GM |

| Model |

Camaro

LS1 |

Corvette

LS1 |

Corvette

LS2 |

Corvette

LS6 |

Corvette

LS7 |

| Displacement |

346

cu in |

346

cu in |

364

cu in |

346

cu in |

427

cu in |

| Bore

x Stroke |

3.90

x 3.62 in |

3.90

x 3.62 |

4.00

x 3.62 in |

3.90

x 3.62 |

4.125

x 4.00 in |

| Comp

Ratio |

10.1:1 |

10.1:1 |

10.9:1 |

10.5:1 |

11.0:1 |

| Cylinders |

8 |

8 |

8 |

8 |

8 |

| Cooling

System |

Liquid |

Liquid |

Liquid |

Liquid |

Liquid |

| Fuel

System |

Multi-port

Injection |

Multi-port

Injection |

Multi-port

Injection |

Multi-port

Injection |

Multi-port

Injection |

| Fuel

Grade |

91

Octane Unleaded or 100 Octane |

91

Octane Unleaded or 100 Octane |

Regular

Unleaded or 91

Octane Unleaded or 100 Octane |

91

Octane Unleaded or 100 Octane |

91

Octane Unleaded or 100 Octane |

| Ignition

System |

Computerized

Electronic - 8 Coils |

Computerized

Electronic - 8 Coils |

Computerized

Electronic - 8 Coils |

Computerized

Electronic - 8 Coils |

Computerized

Electronic - 8 Coils |

| Rated

Power |

325

hp @ 5200 rpm |

350

hp @ 5200 rpm |

400

hp @ 6000 rpm |

405

hp @ 6000 rpm |

505

hp @ 6300 rpm |

| Operating

Power |

300

hp @ 4500 rpm |

320

hp @ 4500 rpm |

350

hp @ 4500 rpm |

350

hp @ 4500 rpm |

400

hp @ 4500 rpm |

| Engine

Torque |

330

ft lbs @ 4500 rpm |

350

ft lbs @ 4500 rpm |

400

ft lbs @ 4400 rpm |

385

ft lbs @ 4500 rpm |

475

ft lbs @ 4800 rpm |

| Propeller

Torque |

463

ft lbs @ 2600 rpm |

499

ft lbs @ 2600 rpm |

|

549

ft lbs @ 2600 rpm |

|

| Reduction

Ratio |

1.7:1 |

1.7:1 |

1.7:1 |

1.7:1 |

1.7:1 |

| Brake

Specific Fuel Consumption Ib/hr @ 3200 R.P.M. |

0.507 |

0.454 |

|

0.500 |

|

| Cabin

Heating |

Forced

Air Hot Water |

Forced

Air Hot Water |

Forced

Air Hot Water |

Forced

Air Hot Water |

Forced

Air Hot Water |

| Air

Conditioning |

Forced

Air Mechanical |

Forced

Air Mechanical |

Forced

Air Mechanical |

Forced

Air Mechanical |

Forced

Air Mechanical |

| Exhaust

System |

SS

Pipes and Mufflers |

SS

Pipes and Mufflers |

Ceramic

coated stainless muffler system |

SS

Pipes and Mufflers |

Ceramic

coated stainless muffler system |

| Rec.

TBO |

1300

h |

1300

h |

|

1300

h |

|

| Water

Take Off |

15

sec |

?

sec |

?

sec |

?

sec |

?

sec |

| Land

Take Off |

10

sec |

?

sec |

?

sec |

?

sec |

?

sec |

| Rate

of Climb |

1075

fpm |

1075

fpm |

?

fpm |

1125

fpm |

?

fpm |

| Power

Loading |

9.8

lbs/hp |

?

lbs/hp |

?

lbs/hp |

?

lbs/hp |

?

lbs/hp |

| Cruise

Speed |

110

mph |

?

mph |

?

mph |

?

mph |

?

mph |

| Fuel

Consumption |

10.8

US GPH |

10.8

US GPH |

?

Imp GPH |

10.8

Imp GPH |

?

Imp GPH |

| Range |

714

mi |

714

mi |

?

mi |

714

mi |

?

mi |

| Endurance |

6.5

h |

6.5

h |

?

h |

6.5

h |

?

h |

| Useful

Load CDN @ 3150 Lbs |

690

lbs |

?

lbs |

?

lbs |

?

lbs |

?

lbs |

| Useful

Load US @ 3250 Lbs |

790

lbs |

?

lbs |

?

lbs |

?

lbs |

?

lbs |

|

Pratt & Whitney PT6A Turbine

Engine |

|

Mark Ward

SkyMark Aviation Services

David Saunders

AviaDesign Services Inc.

|

The Sea

Hornet conversion has a Pratt & Whitney Canada PT6A-20 turbine engine, turning

a specially built Hartzell 3 blade full feather, reversing propeller.

The engine has been

de-rated to 400 SHP.

The subject

Seabee is registered on the Canadian Civil Aircraft Register as C-GNVS

(MSN 465). The listed owner is Mr. R. Wallace of Bellingham,

Washington, USA. However, the modifications and flight testing are

reported to be taking place in California. From the photos it is also seen that

the Seabee has gotten a serious 'nose-job'! Also noted are the

struts on the tailplane. The Turbine Seabee project has been named The

'Sea Hornet'.

The people behind the Turbine Seabee project -

Mr. David Saunders (Avaiadesign Inc.) and Mr. Mark Ward (SkyMark Aviation Services/AviaDesign Services Inc)

- report that they already have accumulated a few

hours on the 'Sea Hornet' and no problems have been experienced so far.

The Sea Hornet was also modified to get

sponsons replacing the wing floats for water stability. However,

this modification was abandoned before completed.

C-GNVS (MSN 465)

PWC PT6A-20 Turbine Engine

Photo: © via Bruce Hinds

Specifications

- Pratt & Whitney Canada PT6A-20 |

| Manufacturer |

Pratt

& Whitney Canada |

| Address |

Canada |

| Model |

PT6A-20 |

| Type |

Two-shaft

axial-plus-centrifugal free-turbine |

| Take

off power |

550

shp to 70° F |

| ESHP |

579 |

| Max

continous power |

550

shp to 70° F |

| Max

climb power |

538

shp |

| Max

cruise power |

495

shp to 59° F |

| |

|

|

|

Simuflight Engine Conversions

|

The most popular of all Seabee engine conversions

available is undoubtedly the Simuflight Lycoming conversions. Developed by Joe McHugh,

the Simuflight conversions represent the majority of all Seabee engine

conversions installed. Sadly Joe McHugh was killed as a passenger

in an airplane accident on 16 June 2003.

In August 2003, Mr. Scott A. Henderson, announced

that he and his sisters intend to continuing the legacy of their

father Joe McHugh, as soon as the estate is sorted out. They

expect to be back in operation beginning in February 2004. Simuflight

will be merging with KenAir Aviation Co. of Sonoma, CA, (Ken Thompson)

and will be building a new facility in Fallon, Nevada. The plan is to

offer complete Seabee maintenance and restoration at the new facility.

Restoration and maintenance work is scheduled to begin on 1 October

2004.

Simuflight has a huge inventory of Seabee parts

along with all the kits that Joe McHugh developed through the years.

McHugh salvaged every Seabee part he ever came across through the

years and if you can't find it in Simuflight's inventory, then it most

likely doesn't exist any longer. Simuflight also have a number

of critical parts that McHugh invested in having remanufactured before

the originals were lost forever.

Simuflight will also be completing a number of STC's that McHugh had

started but never finished. Seabee owners that need parts and kits are

encouraged to make orders now, so that Simuflight can ship them before

they move to Fallon.

All inquiries should be forwarded to the above contact information.

Both the STC Bee (Daubenspeck) and Simuflight

Lycoming engine conversion utilize the the GO-435 and GO-480 engine

series. The geared Lycoming GO-480 engine allows a reduced propeller

speed, 2170 rpm at engine speed of 3400 rpm, with reduced noise as a

result. Data for the GO-480 engine can be found above. Due to the

higher mount of the Simuflight engine conversion, larger propeller

diameters can be installed on the Simuflight (89")

conversions than on the Daubenspeck (84") conversions.

The main features of the Simuflight engine

conversions are as follows:

Cowling

- The Simuflight engine cowling is fabricated from two original Seabee

aluminum cowlings that are modified to form on single piece weighing

only 22 lbs. The cowl is hinged at the forward end and opens

with the release of two lever fasteners - one at each side.

Engine Mount

- Is made almost completely of aluminum and weighs 14 lbs. It

has been statically tested and approved by FAA. The rubber "Lord

Mounts" are mounted at 45º angle to the engine vertical.

The Simuflight mount is designed to transfer engine loads into the

firewall and rear cabin, as on the original Franklin engine

installation.

Exhaust

System - Uses existing Seabee collectors which are welded to

Lycoming flanges, to attach to the cylinders. The exhaust is

routed forward from the cylinders and exhausted upward over the center

of the wing at a 45º angle, to prevent exhaust burn stains and to

reduce noise.

STRuctural

Modifications - The rear firewall section (triangular area

aft of the rear spar) is lowered approximately 10 inches to make room

for the carburetor or fuel injector unit. An access door is

provided on the left side for removal or inspection of the carburetor

components. The rear spar is strengthened on both sides directly

under the engine mount. Forward spar is strengthened by adding a

stiffener below and with the use of a number of "Cherry Loc"

rivets to further attach the web material to the forward spar.

Air

Filetering - Carburetor induction air is filtered at the

intake located forward of the engine to provide the coolest and

cleanest pickup air.

Propeller

- Hartzell constant speed and reversible 2 blade or 3 blade. The

blades are 9333, which are cut off four inches at the factory to give

89 inches blade length.

Gross Weight

- The Simuflight engine conversions allow gross weight increase of

Seabee from original 3150 lbs to 3250 lbs.

STC No:

SA615NW - Installation

of Lycoming GO-435-C2B, GSO-/IGSO-480 series and GO-/IGO-480 series engine

with Hartzell HC-A2V20 and HC-A3VF series propellers; new nacelle and

engine mount; modified front and rear spar and aft firewall; and

associated systems. [Amended 1992-02-28].

STC No:

SA5684NM - Installation

of Lycoming GSO-/IGSO-480 series engine; Hartzell HC-A3V20 propeller;

new nacelle and engine mount; modified front and rear spar and aft

firewall; and associated systems. [Issued 1992-02-19].

|

|

T.A.C. Engine Conversions

|

Owned

by Mr. Randy M. Komko, Transition AirCraft, Inc., (TAC), has developed the

Lycoming IO-540 (250 - 300 hp) and Lycoming TIO-540 (300 - 350 hp) 'direct

drive' engine conversions for the Seabee. The TAC conversions

utilize the 'Daubenspeck'-type cowling.

In co-operation with other parties, Mr. Komko has

also been involved in the development, installation and flight-tests of

a number of GO-480-series engine conversions since 1976, including the

the first GSO-480 (340 hp) Seabee engine conversion installed (N6124K

MSN 310 flying on 1983-10-08).

Here is a list of some of the "TAC"

Seabees:

Randy also offer several other Seabee modifications;

including 6 place interior, droop wingtips, new wing floats, new spray

rails.

TAC holds the following engine conversion STCs:

STC No: SA5652NM -

Installation of a Lycoming TIO-540-A2B engine together with a Hartzell

HC-E3YR-7LF/FLC8468-4R propeller. [STC reissued 1992-03-31].

STC No: SA4330NM -

Installation of a Lycoming IO-540-K engine (N6290K).

Specifications

- Lycoming IO-540-K & TIO-540-A2B |

| Manufacturer |

AVCO

Lycoming |

| Address |

Williamsport,

Pennsylvania, USA |

| Models |

IO-540-K

TIO-540-A2B |

| Approved Type Certificate No. |

1E4

(IO-540K)

E14EA (TIO-540-A2B Issued 1968-04-01) |

| Weight - dry |

438

lbs (IO-540-K)

509 lbs (TIO-540-A2B) |

| Dimension (H x W x

L) |

19.60x34.25x39.34

in |

| Number of Cylinders |

6 |

| Rated Power (T/O) |

300 hp

(IO-540-K)

310 hp (TIO-540-A2B) |

| Rated Speed (T/O) |

2700 rpm (IO-540-K)

2575 rpm (TIO-540-A2B) |

| Idle Speed |

? rpm |

| Reverse Propeller Speed |

? rpm |

| Crankshaft Rotation |

Clockwise |

| Propeller Shaft Rotation |

Clockwise |

| Propeller to Crankshaft Ratio |

1:1 |

| Propeller Shaft |

SAE

A.S. 127 Type 2 Modified |

| Cylinder Head Temperature |

Max.

500 ° F |

| Oil Inlet

Temperature |

Max.

245 ° F |

| Exhaust Gas

temperature |

Max.

1650 ° F |

| Fuel Grade |

100/100LL Aviation |

| Fuel Consumption (Cruise) |

? US gal/hr |

| Fuel Pressure

(above injector inlet air pressure) |

25 to

45 psi |

| Fuel Pressure

(above ambient air pressure) |

-2

to 40 psi (IO-540-K)

-2 to 65 psi (TIO-540-A2B) |

| Compression Ratio |

8.70:1 |

| Piston Displacement |

541.5 cu in |

| Bore |

5.125

cu in |

| Stroke |

4.375

cu in |

| Fuel Pump |

? |

| Fuel Injection |

RSA-10AD1 |

| Turbocharger

(TIO-540-A2B) |

TE0659 |

| Turbocharger

Compression Ratio |

7.30:1 |

| Ignition (dual) |

TCM

S6LN-1208 (Left?)

TCM S6LN-1209 (Right?) |

| Magneto Breaker Point Gap |

?" to

?" |

| Distributor Point Gap |

?" |

| Maximum Drop on Magneto or Distributor |

100 RPM |

| Ignition Timing |

20

ºBTC |

| Firing Order |

1-4-5-2-3-6 |

| Spark Plugs |

? |

| Spark Plug Gap |

?" |

| Valve Clearance |

(lifter

bled down, cold) ?" |

| Starter |

? Volt |

| Generator |

? Volt,

? Ampere |

| Oil Sump Capacity |

12 qts |

| Oil Temp (Max) |

235 ° F |

| Oil Pressure -

Normal (Min - Max) |

55 -

95 psi |

| Oil Pressure (Idle Min) |

25 psi |

| Oil Capacity |

12 qts |

|

|

Turbomeca Astazou II Turbine Engine

|

|

Clark Cameron

Robert A. Mael

Canada

Experimental |

The

Turbomeca Astazou II L turboprop engine installation on Seabee CF-MYT

(MSN 1025) was engineered for owner (?) Bernard Robillard, Montreol, Canada,

by Robert A. Mael; Northeast Engineering and Development Ltd. during

the late 1970ies. The installation was completed on 7 October

1980.

Turboprop Seabee CF-MYT (MSN 1025)

Balsam Lake, Ontario, Canada

Photo: © Blair Robinson

After skis had been installed on the Seabee early in

January 1982, the Turbine Seabee made her first flight on 15 January

1982 with pilot/owner Clark Cameron at the controls. Several test

flights were made during January/February, achieving speeds in excess of

155 mph at 95% power, rate of climb 2700 ft/min at 100% power and fuel

consumption of 12 US gal per hour at 55% power and cruise speed of 110

mph.

Mr. Blair Robinson kindly supplied the following

additional information:

These photographs were taken at fathers dock on

Balsam Lake, Canada. Clark was a close friend of the family, &

his Bee was based on Canal Lake, several miles from dads... This Seabee

was designed, built & flown by the late Clark Cameron. He passed

away suddenly walking away from the Bee after a test flight on skis. The

airplane changed hands several times after his passing, but to my

knowledge has not flown since Clark’s last flight.

I have many fond memories of the Ontario Seabee

club meetings which were held at Clark’s house. He would often

entertain the group by firing up the engine which was mounted in a test

stand chained to his well to prevent it from moving. The engine was a

Turbomeca Astazou. It was extremely noisy, his neighbors must have

loved him! Many club meetings were spent debating the design concepts.

If my memory serves me correct the engine was rated at 450 HP. Clark

promised the DOT he would de-rate the engine to 250 HP. He was never

able to figure out how to de-rate the engine and flew it with the full

450 HP. Clark owned his own machine shop and manufactured most of the

components himself.

One of the pictures shows Clark in the middle, our

dad Eric Robinson on the right and I am on the left. The day that these

pictures were taken both dad and I flew Clark’s Seabee. Unfortunately

Clark passed away early the following year. He proved the airplane would

fly but never got the opportunity to complete the project or solve some

of the issues such as hot starts, prop control, excessive noise and

severely limited range. The airplane was operated under an experimental

certificate only. My brother snapped these pictures with his Polaroid

camera, we wish we had more...

CF-MYT is currently (since 1994-09-26) owned by Mr.

Jean-Marc Rochette; 1905 Rte Du Domaine, St-Raymond, Quebec G3L 3A5,

Canada.

Specifications

- Turboméca Astazou II L |

| Manufacturer |

Société

Turbomeca |

| Address |

Bordes,

F-64320 Bizanos, France |

| Model |

Astazou

II L |

| Type |

Single-shaft

axial-plus-centrifugal turboprop |

| Approved Type Certificate No. |

? |

| Weight - dry |

348

lbs |

| Rated Power (T/O) |

523

shp |

| Maximum

Continuous |

475

shp |

| Rated

Turbine Speed (T/O) |

43 500 rpm |

| Maximum

Continuous Speed |

43

500 rpm |

|

|

W. E. Aerotech Engine Conversions

|

|

W. E. Aerotech Services

West 171 Sanderson Way

Shelton, WA 98584

USA

|

W.

E. Aerotech Services was run by Mr. Donald 'Don' Wallace and Mrs.

Deborah Wallace Aerotech 'remanufactured' a number of Seabees until year 2000, when the company went out of

business. They also had under development a Continental IO-520

engine conversion. STC No:

SA00332SE - Installation

of a Lycoming GSO-480-B2C6 engine (340 hp @ 3400 rpm) and Hartzell HC-A3CF-23L

reversible propeller [Issued 1996-04-26].

|

|

Cukurs Engine Conversions

|

|

Gunars Cukurs

Brazil

|

In

Brazil Mr. Gunnar Cukurs operated several Seabees for more than 4

decades. During those years at least two one-of-a-kind engine

conversions were developed by Cukurs and tested on

the Seabees. When the crankshaft of one the Franklin engines

broke, the Franklin engine was replaced by an Argus AS10C engine from a

pre-WW2 Focke Wulf 56 aircraft! The engine had a power of 240 hp

at 2000 hp. Later a Lycoming GO-435 engine was installed from a

Pilatus PC3 aerobatic aircraft. Finally the now common GO-480-G2D6

engine conversion was installed.

Argus AS10C engine installation

Photo: © via Richard Cukurs

Lycoming GO-435 (?) engine installation

Photo: © via Richard Cukurs

|

|